Don’t Miss the 2025 Peak Season: How to Lock in B2B Inventory for the Best Electric Dirt Bike and Fastest Electric Bike Models

Every spring, the phone rings at the Poleejiek sales desk. On the other end is usually a desperate distributor or a retail chain manager. The conversation is almost always the same: "I have customers walking into my showroom with cash in hand, asking for the best electric dirt bike you have. I need 50 units, and I need them next week."

Unfortunately, by the time that call happens in April, the manufacturing lead time has often stretched well into the summer.

In the high-stakes world of electric mobility, stockouts are not just missed sales; they are an invitation for your customers to walk across the street to a competitor. This is particularly true for high-velocity, viral products like the fastest electric bike categories, where trends move quickly and consumer patience is thin. Inventory is your lifeline.

This guide provides a transparent look at the 2025 supply chain reality. We will move beyond standard sales pitches to discuss the logistics of sourcing, the truth about "American Made" delivery timelines, and how to utilize Poleejiek’s flexible production capacity to ensure your showroom floor never goes empty.

2025 Forecast: Why the "Electric Dirt Bike for Adults" Sector Will Face the Biggest Stockout Wave

As we approach the 2025 fiscal year, data indicates a looming inventory squeeze. For OEM/ODM product managers and distributors, understanding the why behind the shortage is the first step toward mitigating risk.

Demand Surge: The B2C Traffic Spikes

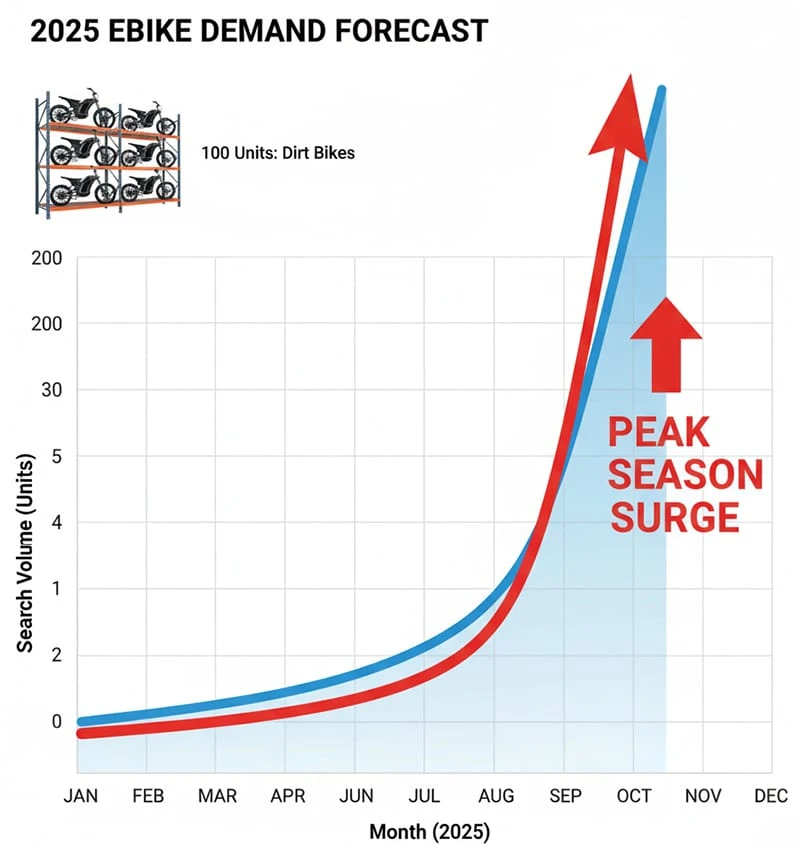

Analyzing search intent and consumer behavior patterns reveals a predictable but aggressive cycle. Google Trends and industry market analysis consistently show that consumer interest in the best electric dirt bike and electric bike for kids categories begins a sharp ascent in late February, peaking between March and May.

During this window, search volume often surges by over 300%. This is driven by tax refunds, improving weather, and the start of the outdoor riding season. However, B2B buyers often react to this surge as it is happening, rather than preparing for it. If you are placing orders when the search volume spikes, you are already too late. The manufacturing queue has likely been filled by forward-thinking distributors who booked their production slots in Q4 of the previous year.

Supply Bottlenecks: The High-Performance Constraint

The shortage is not merely a matter of assembly labor; it is a matter of component scarcity. High-performance units, specifically the fastest electric bike models, require specialized components that are not off-the-shelf commodities.

- High-Discharge Batteries: The cells required for high-torque electric dirt bikes differ from standard commuter e-bikes. Global competition for these high-grade cells is fierce.

- Controllers and Motors: Precision-tuned controllers that handle high voltage without overheating have longer fabrication times.

When global demand peaks, smaller distributors often find themselves pushed to the back of the line by massive global players. By locking in Poleejiek production capacity early, you secure your allocation of these critical components before the global supply tightens.

"Made in China" vs. American Made Electric Bike: The Truth About B2B Lead Times

One of the most common discussions we have with new B2B partners involves the geography of manufacturing and its impact on ebike lead time.

The Myth: Domestic Equals Faster

Many North American distributors operate under the assumption that sourcing from a brand labeled as an American made electric bike guarantees faster restocking speed. The logic seems sound: if the factory is in the US, shipping should take days, not weeks.

The Truth: Supply Chain Interdependence

The reality of the modern electric vehicle supply chain is far more complex. While final assembly may occur in the US or Europe, the core components—specifically the electric bike frame, battery cells, magnets for motors, and semiconductor chips for controllers—are overwhelmingly sourced from Asia.

If a domestic assembler runs out of frames, they are subject to the same ocean freight delays and customs clearances as an importer. Once their supply chain fractures, they face indefinite delays because they lack control over the upstream manufacturing.

The Poleejiek Advantage: Vertical Integration

Poleejiek operates differently. We are not just an assembly plant; we are a vertically integrated manufacturer.

- Frame Control: We weld our own frames. We do not wait for a third-party supplier to ship us the chassis.

- Component Priority: Our long-standing relationships with Tier-1 battery and motor suppliers give us priority allocation.

Data Speaks:

- Industry Average (Third-Party assemblers): 90–120 days lead time during peak season.

- Poleejiek Standard: 45–60 days lead time.

By controlling the process from raw aluminum to final testing, we reduce the variables that cause delays. This reliability is critical when you are calculating your ebike inventory planning.

Poleejiek B2B Inventory Strategy: How to Plan Your Orders

To secure the best electric dirt bike inventory for 2025 without destroying your cash flow, we recommend a three-pronged strategy. This approach is designed to balance risk with opportunity.

Strategy 1: The Pre-Order Window (November/December)

The "Golden Window" for ordering Spring 2025 inventory is right now: November and December.

This period is critical for several reasons:

- Production Queues: You beat the post-Chinese New Year rush.

- Shipping Rates: Ocean freight rates often stabilize before the pre-summer spikes.

- Arrival Time: Orders placed now will arrive in your warehouse in March—perfectly timed for the start of the peak selling season.

If you wait until January to order, your stock arrives in May, meaning you have missed half of the prime selling window for the fastest electric bike models.

Strategy 2: Utilizing the Mixed Container (MOQ Flexibility)

A major pain point for growing distributors is the Minimum Order Quantity (MOQ). You might hesitate to order a full 40-foot container of a single high-end electric dirt bike for adults because of the capital tie-up and storage space risks.

Poleejiek solves this with our Mixed Container policy. We allow B2B partners to diversify their risk within a single shipment.

Example Container Configuration:

- 20 Units: High-performance best electric dirt bike (The flagship draw).

- 30 Units: Mid-range fastest electric bike commuters (High turnover).

- 50 Units: Entry-level electric bike for kids (Volume sellers).

This strategy ensures you have a diverse portfolio to offer different customer segments without over-committing to a single SKU. It keeps your inventory dynamic and your turnover rate high.

Strategy 3: Cash Flow and the "Rent to Own" Model

Inventory requires capital. We understand that distributors face cash flow pressures. One emerging trend we are seeing among successful partners is the implementation of a rent to own electric bike program for end-users.

This model lowers the barrier to entry for consumers who want a high-end electric dirt bike but cannot pay the full price upfront. For the B2B buyer, this ensures steady monthly revenue. Poleejiek supports this model by offering flexible payment terms for large-volume, recurring B2B orders. By aligning our payment structures with your business model, we ensure that capital constraints do not prevent you from stocking the necessary inventory.

Technical Considerations for B2B Buyers: Quality in the Rush

When rushing to beat lead times, quality cannot be sacrificed. Even the fastest electric bike is worthless if it returns to your shop for warranty repairs within a week.

The Pre-Shipment Inspection (PSI)

At Poleejiek, regardless of the rush season, every unit undergoes a rigorous PSI.

- Battery Aging Test: ensuring cells are balanced and stable.

- Road Simulation: Dyno-testing motors to ensure torque specs are met.

- Waterproofing Checks: Critical for dirt bikes intended for off-road use.

For our OEM/ODM partners, we provide detailed QC reports prior to shipping. This transparency allows you to assure your downstream dealers that the inventory arriving is ready to sell out of the box, minimizing after-sales friction.

Conclusion: Inventory is the Oxygen of Your Business

In the B2B world, the most expensive bike is not the premium electric dirt bike for adults sitting in your warehouse—it is the bike you didn't have in stock when a customer was ready to buy.

The 2025 season will favor the prepared. The demand for the best electric dirt bike and electric bike for kids is projected to grow, but supply chains remain fragile for those who rely on just-in-time ordering.

By leveraging Poleejiek’s vertical integration, flexible MOQ, and mixed container capabilities, you can secure your position as a reliable supplier in your region. Do not let lead times dictate your revenue.

Next Steps for B2B Buyers

Don't wait until your competitors are sold out to realize the urgency.

- Contact the Poleejiek Sales Team today to discuss your Q1 2025 production slot.

- Download our "2025 Spring Best-Sellers Order Guide" to see which configurations of the fastest electric bike are trending in your region.

Ensure your dealership is the one customers rely on. Plan ahead, order smart, and ride the 2025 wave to profitability.