Ebike Battery & Motor Guide: B2B After-Sales & Parts

For a B2C customer, the ebike journey is about excitement: speed, range, and convenience. For a B2B distributor, integrator, or OEM product manager, that journey often ends with a single, massive headache: the "after-sales nightmare."

The B2C customer's biggest anxieties—an aging ebike battery or a failing electric bikes motor—don't just disappear. They are transferred directly to you, the business partner.

This is the moment of truth for your business. Your long-term reputation and profitability are not defined by how many units you sell. They are defined by what happens when the 100th customer returns with a problem and you're asked to provide a solution—not in weeks, but within 48 hours.

Can you do it? Or will that bike, and your relationship with that client, begin to gather dust?

This guide moves beyond the B2C-level questions ("How far can this battery go?"). It dives deep into the core issues that determine B2B success or failure: the reliability, replaceability, and long-term supply chain of the most critical components. We will dissect the battery, the motor, and the essential spare parts ecosystem that separates a profitable partnership from a logistical and financial dead end.

The Core of the Core: The Ebike Battery (Your #1 After-Sales Challenge)

The ebike battery is the single most critical, expensive, and volatile component in your inventory. It is a consumable item with a finite lifespan, and it is the source of the vast majority of all warranty claims, technical support tickets, and customer complaints.

For a B2B partner, treating the battery as a simple "spec" is a catastrophic mistake. You must analyze it from the perspective of a service center manager.

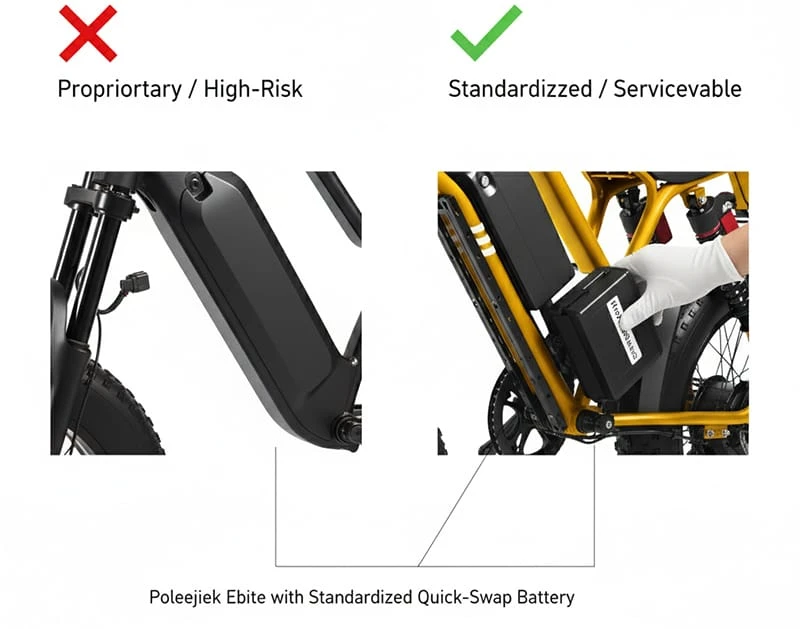

The B2B Sourcing Trap: "High Capacity" vs. "High Maintainability"

Your retail-focused customers will be mesmerized by high capacity, measured in Amp-hours (Ah) or Watt-hours (Wh). They see a bigger number and equate it with a better bike.

You, the B2B buyer, must resist this trap. You must prioritize maintainability and replaceability.

When evaluating a potential supplier, ask these questions:

- Connectors: Does the battery use a fragile, multi-pin proprietary connector that will bend and fail, or does it use robust, industry-standard connectors (like an XT60 or XT90 for power)?

- Housing: Is this battery built into a "unicorn" frame? Is the casing a unique, complex mold that will be discontinued the moment the supplier launches their next model?

- Removal: How many steps does it take to remove the battery? Does it require special tools? Can a non-technical user (or a basic service tech) swap it in under 60 seconds?

A "high-capacity" battery that is molded into a frame or uses a fragile, custom connector is not an asset. It is a time bomb. When it fails, the entire ebike is often rendered useless, and your only solution is a costly, full-unit replacement.

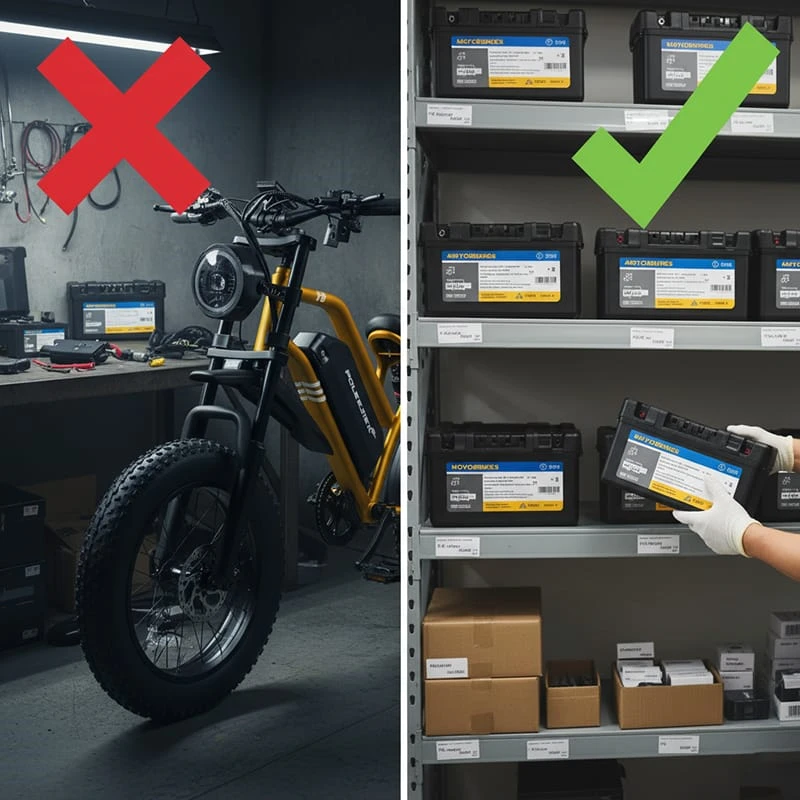

Why Replaceability Trumps Raw Range in the B2B Model

Consider two scenarios:

- Bike A (The "Range King"): A 100-mile range battery. It's a custom-molded design. A replacement, if available, costs $900 and has a 16-week lead time from the factory.

- Bike B (The "Service Champion"): A 50-mile range battery. It uses a standardized slide-in docking system. You can keep 20 replacements in your local warehouse. A replacement costs $350 and can be shipped to your customer overnight.

Which bike builds a better, more profitable business?

Bike B, without question. Poleejiek designs its platforms around standardized battery docks. This allows our B2B partners to easily procure and stock batteries for electric bikes that can service multiple models, drastically simplifying inventory and ensuring you can solve a customer's "dead bike" problem on the first call.

The electric bike battery 48v: Your Baseline for Safety and Stock

While various voltages exist, the 48V system has emerged as the clear market leader for performance and reliability. As a B2B purchaser, standardizing on a primary voltage like 48V is a critical inventory strategy. It simplifies your service department, your charger stock, and your replacement battery purchasing.

But voltage isn't the only consideration. Your number one non-negotiable must be safety certification.

When you import or distribute ebikes, you are not just selling a product; you are assuming liability. An electric bike battery 48v that is not certified to UL 2849 (the comprehensive standard for the entire ebike electrical system) is an unacceptable financial and legal risk.

Any potential ebike parts supplier must be able to provide full UL certification documents for the entire system (battery, charger, and motor/controller). A simple "UL-tested cell" is not enough. This certification is your first line of defense against catastrophic failures and your primary proof of E-E-A-T (Expertise, Authoritativeness, Trustworthiness) in the market.

Building Your Battery Stock: Moyo's B2B Rapid Replacement Program

A supplier's job shouldn't end when the container arrives at your port. A true B2B partner understands that their success is tied to your ability to service the product.

That's why we've moved beyond the traditional sales model. Poleejiek provides a B2B partner-only priority channel for critical part electric bike shipments. We guarantee the availability of replacement batteries for all models for a minimum of five years post-production, ensuring your service centers are never left waiting and your customers are never left stranded.

The Drivetrain: Electric Bikes Motor Maintainability Analysis

If the battery is the ebike's heart, the motor is its muscle. It's also the second-most-likely point of catastrophic failure. The design choice of the motor has profound implications for your ebike repair and maintenance strategy.

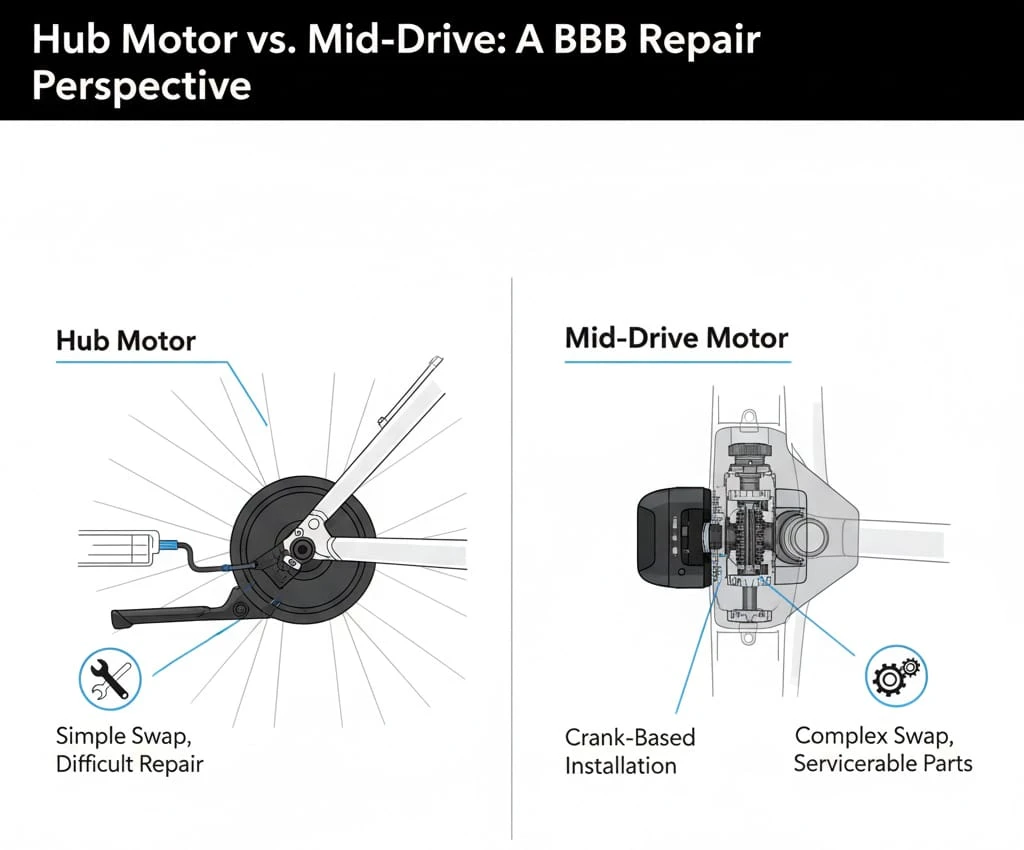

Hub Motor vs. Mid-Drive: A B2B Repair Perspective

The market is dominated by two architectures. Your B2C customer may have a preference, but your B2B decision must be based on total cost of ownership and repair logistics.

-

Hub Motors (Rear or Front Wheel)

- B2B Pro: The entire system is self-contained. For repairs, it's a simple "plug-and-play" swap. Your tech removes the wheel, disconnects one cable, and installs a new motor wheel. This is fast, requires minimal training, and is ideal for high-volume fleets (rentals, delivery) where vehicle uptime is the single most important metric.

- B2B Con: The motor itself is a "black box." If the internal gears strip or a sensor fails, 99% of service centers will not attempt an internal repair. The entire motor-wheel assembly is discarded.

-

Mid-Drive Motors (Mounted at the Crank)

- B2B Pro: The motor is serviceable. A trained technician can open the motor casing to replace worn-out nylon gears, clutches, or torque sensors. This is a much lower-cost repair than replacing the entire unit. It also separates the motor from the wheel, meaning wheel maintenance (flat tires, broken spokes) is standard.

- B2B Con: Repair requires significantly more expertise and specialized tools (like a crank puller and motor lockring tool). The replacement process is more complex than a simple wheel swap.

Your choice depends on your business model. Poleejiek offers documented, serviceable models in both categories, allowing you to build a fleet that matches your service capabilities.

The B2B Nightmare: Proprietary and "White-Label" Motors

This is the hidden trap that has bankrupted distributors. A factory offers an incredible price on a new model featuring an unbranded, "white-label" motor. You place a large order. Six months later, you have a 3% failure rate.

You contact the supplier for replacement motors. Their response: "Sorry, that motor has been discontinued. We now use this new one, but it has a different mounting bracket and cable connector."

Your entire inventory is now unsellable and unserviceable. The bikes are effectively bricked.

The Poleejiek Guarantee: A Transparent and Supported Drivetrain

A professional B2B ebike parts supplier must provide a transparent drivetrain. This is our commitment:

- Branded Mainstream Motors: We primarily use motors from established, mainstream brands (like Bafang, Bosch, Shimano, etc.) that have their own global parts and service network.

- Fully Documented In-House Motors: When we develop our own proprietary motor for a specific performance advantage, it is not a "black box." We provide our B2B partners with the complete ebike technical manual, service diagrams, and a guaranteed supply chain for all internal repair components, including sensors, controllers, and gear assemblies.

You will never be left with a "black box" you cannot service.

"How Do I Get Every Other Part Electric Bike?" (Solving the B2B Parts Fear)

The battery and motor are the big-ticket items, but they aren't what causes the most frustration. The true "after-sales nightmare" is often the small, unique, inexpensive part that you cannot find.

The Root of the Fear: The "One-Part-Missing" Catastrophe

nbsp; Imagine this real-world scenario: A distributor purchased 50 units of an electric dirt bike model. Two units arrive with screens that were cracked during shipping. Three more have controllers that fail within 30 days.

The distributor contacts the supplier: "I need five replacement controllers and two displays."

The supplier replies: "We don't sell those parts individually. You will have to buy a new, complete wiring harness kit for $300."

Or worse: "We can send them, but they must be part of your next container order in three months."

Now, that distributor has five dead bikes, five angry customers, and thousands of dollars in capital tied up in useless inventory, all because of a single, $40 proprietary controller. This fear is a primary driver of ebike after-sales support anxiety.

The Poleejiek "Total B2B Parts Solution"

A comprehensive ebike parts supplier does not just sell bikes; they sell a complete service ecosystem. Our solution is built on three pillars to eliminate this fear.

1. Prioritization of Standardized Components

We intentionally design our bikes using non-proprietary components wherever possible. We use brake systems from Tektro and Shimano, tires from Kenda, and chains from KMC. This means you aren't locked into us for basic consumables. You can source these standard parts locally, reducing your costs and speeding up repairs.

2. Guaranteed Supply for Proprietary Parts

For parts that must be proprietary to our design (like a specific electric bike frame component, a custom battery case, or a unique display mount), we provide a contractual 5-Year Parts Supply Guarantee. This is our written promise that you will be able to service the unique aspects of our products long after the initial sale.

3. The B2B Partner Parts Portal

This is the system that ties it all together. Our qualified B2B partners get exclusive access to our online parts portal. Here, you can:

- Access Exploded-view Diagrams (EXDs) for every model.

- Find official Part Numbers for every single screw, bracket, and cable.

- View real-time stock levels and partner pricing.

- Place low-MOQ (Minimum Order Quantity) parts orders that ship immediately, independent of your next container order.

This system transforms ebike repair and maintenance from a chaotic guessing game into a streamlined, professional process.

Conclusion: Choosing a Supplier is Choosing Your After-Sales Department

When you sign a B2B supply contract, you are not just buying a product. You are inheriting that product's entire future of technical problems, warranty claims, and service needs.

A "sell-and-run" supplier—one who focuses only on the initial unit price—is simply transferring the largest and most unpredictable costs of business directly onto you. They sell you the bike and leave you with the "after-sales nightmare."

A true B2B partner, like Poleejiek, functions as an extension of your own team. We absorb the complexity, provide the systems, and guarantee the parts supply chain so you don't have to. We believe that our job is to help you solve your customer's problem, not just create a new one for you.

Before you place your next major ebike order, ask your potential supplier these questions.

Your B2B After-Sales Self-Audit Checklist

- Can you provide complete UL 2849 certification for the entire ebike system?

- Do you offer a 5-year replacement guarantee for the ebike battery?

- Can I get a complete technical manual and internal repair parts for your electric bikes motor?

- Do you have a B2B portal with exploded-view diagrams and part numbers for every component?

- Can I place small, express-air orders for part electric bike components, or must I wait for my next container?

Their answers will tell you everything you need to know.

[Call to Action]

Don't wait until a customer's bike is on the repair stand to discover your supplier has left you stranded. Contact the Poleejiek B2B team today.

Request our "B2B Distributor After-Sales Support Whitepaper" and ask for a demo of our complete B2B Parts Portal and Catalog. Let us show you how a true partnership can eliminate your after-sales nightmare for good.